Speaker:

Mr. Raymond (Ray) Wensley, P.Eng.

Abstract:

Electricity is the lifeblood of modern society and the North American Power electric system is the largest in the world.

In Alberta, the supply of energy and many ancillary services are managed through deregulated markets. The AESO’s System Control Centre is the brain that directs the Alberta System and the nervous system that feeds it is made up of thousands of SCADA points. It is from these SCADA points that advanced applications analyze the reliability and stability of the electric system and provide System Controllers with the Situation Awareness to run the system. This talk will describe the interplay of Markets and control systems and the role of SCADA in “keeping the lights on”.

- How the Alberta Electric System fits inside the North American System

- How the Markets interact with the AESO Control Centre

- SCADA and the data provided to the Control Centre

- The communication system that allows control of the Grid

- The control of generation and transmission

- Supply and demand balance

- Situational Awareness

Raymond Wensley

Raymond (Ray) Wensley, P.Eng. graduated from the University of Saskatchewan in 1979 with a major in Power Systems and a minor in Electronics. After graduating he joined Calgary Power Ltd. (later becoming TransAlta Utilities). In 1982 he became part of the team to build the first Energy Management System (EMS) in the province. Over the next 17 years Ray was involved in the development of the EMS’s Automatic Generation Control, State Estimator, Dispatcher’s Load Flow, Contingency Analysis and Dispatcher’s Training Simulator. In 1998, he joined the PowerPool of Alberta (later becoming the Alberta Electric System Operator) and was part of the team that built the first provincial EMS. In 2007 Ray become Project Engineer on the AESO’s EMS replacement project that went operational in 2009. Since 2012 he has been part of the Operations Business Solution group as an EMS Business Solution Analyst.

RSVP:

IEEE_CSS_Dist@shaw.ca

Abstract

Safety Instrumented Systems are becoming more prevalent in Canadian process industries as the related international standards are starting to become recognized and applied in North America. In Alberta, most control systems installations in the O&G industry now have requirements for safety instrumented systems. In Calgary the concept of performance based safety integrity has become an engineering precept for most green-filed and brownfield industrial projects. The achievement of safety integrity for these projects depends on a number of factors such as the number of available layers of protection for any given hazard, the safety system’s architecture, the quality of maintenance activities, the frequency of proof tests, and the affected equipment’s reliability. In this talk we will provide a brief introduction to safety instrumented systems and the application of the IEC 61511 safety lifecycle to process the oil and gas industry. We will then discuss in greater detail how the safety integrity of Safety Instrumented Functions is evaluated and finish with a short case study on methods to calculate the achieved proof test coverage in a given situation.

Dave Goerzen

Dave Goerzen CET, CFSE comes to us from Autopro Automation Consultants. Before graduating with Honors from SAIT’s Industrial Instrumentation Technology program in 1996, Dave earned both a BSc in Physics and a BA in Math. His early experiences include both field and facility operations production as well as electrical and instrumentation maintenance and supervision in the mining, lumber, and upstream oil and gas industries. Upon graduating from SAIT, Dave joined Kenonic Controls where he eventually became a Senior Technical Consultant for Emerson Process Management. His Safety Instrumented System on site experiences there included both green and brownfield projects for facilities in locations as far afield as Nigeria, Angola, and Russia. Before moving from Emerson to Autopro in the spring of 2013, Dave completed a mandate as the Safety Instrumented Systems lead for Imperial Oil’s Kearl Oil Sands Project north of Ft. McMurray, driving that facility’s SIS design from the early FEED stage through its start-up late in 2012. As a Certified Functional Safety Expert, Dave has experience in both the theoretical life-cycle engineering activities as well as practical implementation of the IEC 61511 and ISA 84 standards to the tune of applying over 30,000 dedicated field devices to the protection of process facilities.

Stephane Boily

Stephane Boily P.Eng., CFSE graduated from École Polytechnique in Montreal in 1988 in Electrical Engineering with specialization in Automation and Controls. Stephane worked in Eastern Canada as a control systems specialist until he moved to Calgary to join Kenonic Controls Ltd in 1996 which was acquired by Emerson in 2000. Stephane was the lead Safety Instrumented Systems (SIS) engineer for the ExxonMobil Kizomba A production platform and FPSO which produced and is still producing a quarter of a million barrels of oil per day. In 2004, Stephane received the Certified Functional Safety Expert (CFSE) certification. At Emerson Stephane was the SIS implementation manager and group manager. He was involved in the development of engineering processes for the implementation of SIS at Emerson which were subsequently certified by TUV Nord in 2006. Stephane continued with Emerson until February 2009 when he joined exida Canada, a subsidiary of exida, leaders in functional safety and product safety certification. In October 2011, Stephane joined Autopro as their SIS technology manager where he is involved in risk analysis, Safety Integrity Level determination and verification, SIS implementation, and various other safety lifecycle activities.

RSVP:

IEEE_CSS_Dist@shaw.ca

Abstract:

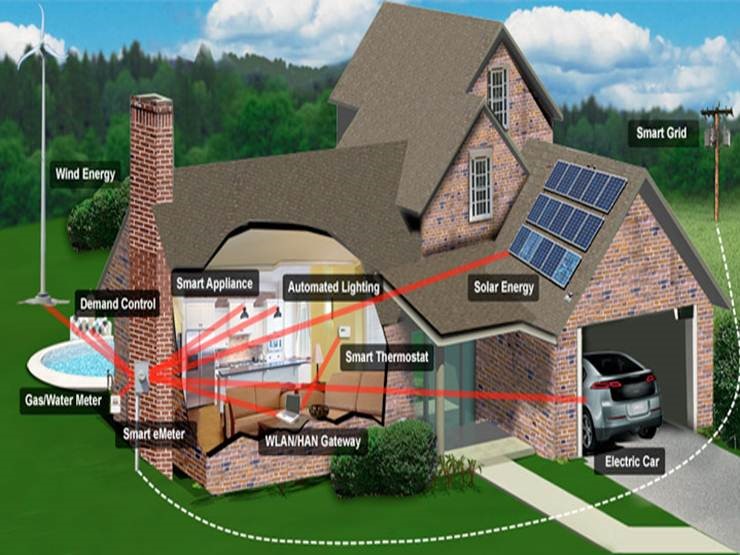

The interest and pace of adoption of Demand Response (DR) by electric utility in North America continues to grow rapidly. An example of this is the top finding in a key report just released (January 2014) by the California Energy Commission stating “the urgency to scale-up demand response is high if California is to maintain a reliable electric system….” Demand Response can be defined as the ability to reduce electricity consumption when electricity prices are high or the reliability of the electric grid is threatened. Common examples of demand management include: raising the temperature of the thermostat so the air conditioner does not run as frequently, slowing down or stopping production at an industrial operation, dimming/shutting off lights, or any explicit action taken to reduce load in response to short-term high prices or other control signal. Demand Management also can result in cost savings due to incentives or lower electric rates.

DR offers many potential benefits to such as improving grid reliability, reducing peak demand and supporting the integration of renewable energy resources such as wind and solar. This presentation will address the types of DR, uses and benefits, typical architectures, technologies and standards, future trends, challenges and lessons learned.

Ron Farquharson

Ron Farquharson, RET, SMIEEE is a Principal Consultant and utility automation professional with expertise in many areas of electric utility transmission and distribution automation including data communications, substation gateways, synchrophasor data measurement, equipment condition monitoring and standards. He has assisted utilities with program reviews, requirement developments and procurement documentation. In recent years Ron has also been assisting utilities with their technology investment and deployment planning. As part of these engagements, he has developed an effective methodology for roadmap development that includes technology assessments, standards maturity, gap analysis, regulatory compliance and risk assessments. A key part of the methodology is a highly collaborative approach based on use-cases to identify multi-stakeholder requirements. Clients have included leading firms such as Electric Power Research Institute (EPRI), FirstEnergy, Duke Energy, California ISO, Salt River Project, Southern California Edison and Hydro Quebec. In addition, Ron led a team that prepared an extensive report for EPRI summarizing key methodologies, positive outcomes, lessons learned, recommendations and best practices based on results of eight of the roadmaps.

Ron is the President of the DNP User Group, is a Senior Member of the IEEE and is Chair of two PES working groups related to IEEE Std. 1815 (DNP3) and IEC 61850. He also serves on the Advisory Committee for DistribuTECH as the Substation Automation Track Chair.

Prior to his work as a Principal Consultant Ron spent 25 years with GE serving in a range of roles primarily related to Product Management and Product Leadership in the area of Substation Automation.

RSVP:

IEEE_CSS_Dist@shaw.ca

Abstract:

With the progress of field digital technology, field instruments have increasingly more information and diagnostics data to maintain them in pro-active manner. Engineers require an effective plant asset management system in order to support condition based predictive maintenance strategy for field instruments. This presentation will discuss the implementation criterion to be considered for successful use of plant asset management system in plant environment to ease both maintenance and operational needs. In particular, the following topics will be presented

- PAMS (Plant Asset Management system)

- Role and Functionality of PAMS

- Use of PAMS

- Work processes

- PAMS champion

- Training

Amit Ajmeri

Amit Ajmeri is a consultant for asset management solutions and services for Yokogawa Corporation of America in Houston, TX and has worked there since 2002. He spent the first 12 years of his career at Emerson supporting new technology like FF and promoting interoperability. He is a senior member of ISA and has represented Yokogawa in various marketing committee in ISA (ISA013, ISA104, ISA100 and ISA108), FDT Organization, HART and Fieldbus Foundation.

RSVP:

IEEE_CSS_Dist@shaw.ca

Abstract

This session will provide information on some major enhancements that have either been recently released or that are currently under development for the Distributed Network Protocol (DNP3). DNP3, now known as IEEE Std 1815, has become one of the most popular utility-specific communications protocols and is used at over 75% of North American electric utilities. This session will describe how secure authentication has been added to the protocol to address the possibility of cyber attacks; how a profile has been developed for using DNP3 with smart inverters such as photovoltaic distributed energy resources (DER); how a specification is underway to convert between DNP3 and IEC 61850; and how the DNP Users Group has addressed recent concerns about software vulnerabilities in DNP3 implementations. This session should be useful both for attendees who are familiar with DNP3 and also for those who are mostly concerned how it is being enhanced to meet the current needs of the utility industry.

Grant Gilchrist

Grant Gilchrist, P. Eng., is a Principal Consultant on the Smart Grid Engineering Team at EnerNex Corporation. He is a member of several utility data communications standards bodies including the IEC working groups for SCADA, substation automation, protocol security, and interoperability. He is a founding member of the Technical Committee for the Distributed Network Protocol (DNP3). He has helped several major utilities develop technical requirements for their Advanced Metering Infrastructures and other Smart Grid programs, and was editor of the IEC 62351-5 standard for security of the IEC 60870-5 and DNP3 protocols. He specializes in visualizations of the Smart Grid and developed the NIST Smart Grid Framework “cloud” diagrams.

Before joining EnerNex, Grant spent a total of 17 years developing embedded data communications software for GE Energy and Nortel Networks. He has a Bachelor of Applied Science in Systems Engineering from the University of Regina, Saskatchewan, and is a registered Professional Engineer in the province of Alberta, Canada.

Registration

Abstract

This presentation shares information and research regarding technical solutions that secure industrial control systems. The presentation explores the use and efficacy of firewalls, virtual private networks, authentication proxy services, and application whitelisting as well as other methods to secure a control systems. The presentation shares how these methods provide a means mitigate advanced persistent threats (APTs), such as found in Stuxnet.

The presenter explores areas that are able to improve overall automation system robustness including safety, reliability, and security. For example the presentation looks at inclusion of configuration and change control at the intelligent electronic device layer and how this addresses security and operational considerations for various industrial segments such as power, oil, gas, and water.

Dwight Anderson, CISSP, GSEC, PE (Texas)

Dwight Anderson is an electrical engineer graduated from Steven’s Institute of Technology, Hoboken, New Jersey, USA. Dwight also holds an AAS Electrical Engineering Technologies degree from Middlesex County College, Edison, New Jersey, USA. Dwight is presently working as a Control Systems security expert at Schweitzer Engineering Laboratories, Inc . Pullman, Washington, He provides cybersecurity services for customers in order to increase their compliance to cybersecurity regulations (such as NIST and NERC CIP). He provides NERC CIP training and attends DHS training regarding the approaches hackers might take to exploit critical infrastructure control systems. Dwight worked for Agilent Technologies/ Hewlett-Packard Loveland, Colorado, from 1997–2003 as business development manager.

During this period, Dwight managed a small team to design and create a submarine antenna switching system, generating a five year business opportunity with the U.S. Navy, Australian Navy, as well as the Royal British Navy. The design passed Mil-Spec-461 (EMI and RFI) and Mil-Spec-901 (mechanical shock). Dwight also managed a small team to design an avionics test system for use onboard U.S. aircraft carriers.

Dwight is quite active in various industrial and government organizations addressing control systems cyber security issues. The following are only some of the control systems security activities that he has been involved in:

US Dept. Of Homeland Security CERT – Operational Security (OPSEC) for Control Systems – 2014

US Dept. Of Homeland Security CERT – Cyber Security for Industrial Control Systems – 2014

Defcon – 2012

ISSA Palouse Chapter, communications director, 2009.

Chem. ITC Cyber Security Team, co-chair, 2009.

DHS – Control Systems Cyber Security Advanced Training (Red Team vs. Blue Team), 2008

(ISC) 2 CISSP, 2007.

SANS GIAC GSEC Security Boot Camp, 2007.